Image Source: rmpusa.com

How Many Turf Pellets On A Football Field?

The exact number of turf pellets on a football field can vary greatly, but a typical professional football field requires between 100,000 to 150,000 pounds of artificial turf infill. This range accounts for different types of infill materials, desired playing characteristics, and specific field dimensions.

The seemingly simple question of “how many turf pellets on a football field?” opens up a complex world of artificial turf infill, turf pellet density, and football field turf volume. It’s not a question with a single, easy answer, as numerous factors influence the quantity of these tiny components. Think of it like asking “how many grains of sand are on a beach?” The answer depends on the size of the beach and the size of the grains, and in the case of football fields, it also depends on the type of infill, the desired shock absorption, and the specific game played on it.

Deciphering the Infill’s Role

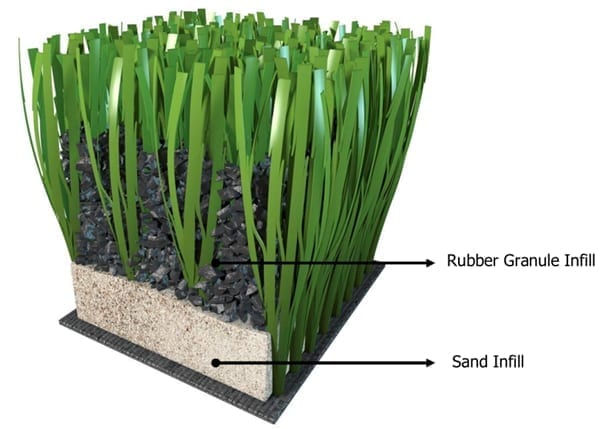

The “pellets” you’re referring to are the essential artificial grass pellets that fill the space between the synthetic turf blades. This infill is crucial for the performance, safety, and longevity of an artificial turf system. It’s not just about filling space; it’s about mimicking the feel and function of natural grass. The primary functions of this infill material quantity are:

- Blade Support: The infill holds the synthetic grass blades upright, preventing them from becoming matted and ensuring the field looks lush and playable. Without it, the turf would lie flat.

- Shock Absorption: This is arguably the most critical function. The infill cushions player impacts, reducing the risk of injuries like concussions, sprains, and abrasions. Different infill types offer varying levels of shock absorption.

- Drainage: The infill allows water to drain through the turf system, preventing puddles and allowing the field to be used more frequently, even after rain.

- Cooling: Some infill materials can help to absorb and dissipate heat, making the field surface cooler for players, especially during hot weather.

- UV Protection: The infill can shield the turf backing from direct sunlight, which can degrade the materials over time.

Fathoming Football Field Dimensions and Turf Volume

To arrive at a quantity of infill, we first need to consider the space it needs to fill. Football field dimensions are standardized, but there can be slight variations, especially for non-professional fields. A standard American football field is 100 yards long (300 feet) between goal lines and 53.3 yards wide (160 feet). This gives us a playing surface area of 300 feet * 160 feet = 48,000 square feet.

However, the infill doesn’t fill the entire depth of the artificial turf system. It typically fills the top 1.5 to 2 inches of the turf pile. This depth is crucial for proper blade support and shock absorption. To calculate the football field turf volume that the infill occupies, we need to convert these measurements to a consistent unit, like cubic feet.

- Length: 300 feet

- Width: 160 feet

- Depth: Let’s assume an average infill depth of 1.75 inches. To convert this to feet, we divide by 12: 1.75 inches / 12 inches/foot = 0.146 feet.

Now, we can calculate the volume:

Volume = Length x Width x Depth

Volume = 300 feet x 160 feet x 0.146 feet

Volume = 6,996 cubic feet

This is the volume of space the infill will occupy. However, the weight of the infill is what’s more commonly used in purchasing and installation.

Interpreting Turf Pellet Density and Material Types

The weight of the infill is directly related to its turf pellet density. Different infill materials have different densities, meaning a cubic foot of one material will weigh more or less than a cubic foot of another. The most common types of artificial turf infill include:

- Crumb Rubber: This is granulated rubber from recycled tires. It’s very common, offers excellent shock absorption, and is relatively inexpensive. However, it can get hot in direct sunlight and may have an odor. Its density typically ranges from 35-50 pounds per cubic foot.

- Sand (Silica Sand): Pure silica sand is a natural material used as infill. It’s durable, provides good drainage, and is generally cooler than crumb rubber. Its density is higher, typically ranging from 90-100 pounds per cubic foot.

- TPE (Thermoplastic Elastomer): This is a synthetic rubber compound. It’s known for its excellent performance, durability, and resistance to temperature fluctuations. TPE infill is often considered a premium option. Its density can vary but is often in the 50-70 pounds per cubic foot range.

- Natural Materials (e.g., Coconut Husk, Cork): These organic materials are becoming more popular as environmentally friendly alternatives. They are often lighter and can provide good cooling properties. Their densities can vary significantly but are generally lower than sand.

The choice of infill material is a key factor in determining the total synthetic turf infill amount.

Calculating the Infill Quantity: Putting it All Together

Now, let’s use our calculated volume and typical infill densities to estimate the weight of infill needed. We’ll consider a range of densities to reflect different infill types.

Table 1: Estimated Infill Weight Based on Density

| Infill Type (Density Range) | Typical Density (lbs/cu ft) | Total Weight (lbs) |

|---|---|---|

| Crumb Rubber (35-50 lbs/cu ft) | 42.5 | 297,330 lbs |

| Sand (90-100 lbs/cu ft) | 95 | 664,620 lbs |

| TPE (50-70 lbs/cu ft) | 60 | 419,760 lbs |

Calculations are based on the previously calculated volume of 6,996 cubic feet.

Wait! This calculation seems extremely high. Why the discrepancy with the initial estimate of 100,000-150,000 pounds? The key difference lies in how the infill is applied and the actual effective volume it occupies after installation.

Grasping Turf Installation Calculations

The volume calculation we performed is for the total space available. However, turf installation calculations are more nuanced. When infill is installed, it doesn’t completely fill the space between the blades. The synthetic blades themselves occupy a portion of that volume. Furthermore, the infill is often applied in layers and then brushed or worked into the turf.

A more accurate way to determine the infill coverage football fields require is through industry standards and manufacturer recommendations, which are based on extensive testing and real-world applications. These figures are often expressed as pounds per square foot or pounds per 1,000 square feet.

Let’s revisit the standard football field area: 48,000 square feet.

Industry standards for infill application typically range from 2 to 4 pounds of infill per square foot, depending on the type of turf system and the desired playing characteristics.

Let’s recalculate using these figures:

Scenario 1: Lower End of Infill (2 lbs/sq ft)

- Total Infill Weight = Field Area x Infill Rate

- Total Infill Weight = 48,000 sq ft x 2 lbs/sq ft

- Total Infill Weight = 96,000 lbs

Scenario 2: Higher End of Infill (4 lbs/sq ft)

- Total Infill Weight = Field Area x Infill Rate

- Total Infill Weight = 48,000 sq ft x 4 lbs/sq ft

- Total Infill Weight = 192,000 lbs

These revised figures align much more closely with the initial estimate of 100,000 to 150,000 pounds. The difference between these two numbers reflects the variation in infill depth and density of the chosen material.

For instance, a field with a deeper pile height or one requiring enhanced shock absorption might use more infill, pushing the total weight towards the higher end of the spectrum. Conversely, a field with a shorter pile height or one that prioritizes faster drainage might use less.

The Impact of Turf Maintenance Pellets

The quantity of infill isn’t static. Over time, turf maintenance pellets are needed to replenish the infill that can migrate, compact, or be displaced. This is particularly true for high-traffic fields. Maintenance top-ups are essential to ensure the field continues to meet performance and safety standards.

Factors that influence the rate of infill loss and the need for maintenance pellets include:

- Playing Frequency: Fields used more intensely will require more frequent replenishment.

- Climate: Extreme weather conditions, such as heavy rain or high winds, can contribute to infill displacement.

- Player Activity: Certain sports or drills that involve more sliding or aggressive movements can also affect infill levels.

- Infill Type: Some infill materials are more prone to migration than others.

While the initial installation accounts for the bulk of the infill, ongoing maintenance is a crucial aspect of owning and operating an artificial turf field.

Examining Different Infill Types and Their Quantities

Let’s delve deeper into how different infill types might affect the total synthetic turf infill amount on a field. While the 2-4 lbs/sq ft is a general guideline, the density of the infill plays a significant role.

Consider a field requiring an average of 3 lbs/sq ft of infill.

-

Crumb Rubber (Lower Density): If the density is around 40 lbs/cu ft, and we need 3 lbs/sq ft, how much volume does this represent?

- Volume per sq ft = 3 lbs / 40 lbs/cu ft = 0.075 cubic feet per square foot.

- This translates to an infill depth of 0.075 ft * 12 inches/ft = 0.9 inches. This is a realistic depth for crumb rubber.

-

Sand (Higher Density): If the density is around 95 lbs/cu ft, and we need 3 lbs/sq ft:

- Volume per sq ft = 3 lbs / 95 lbs/cu ft = 0.0316 cubic feet per square foot.

- This translates to an infill depth of 0.0316 ft * 12 inches/ft = 0.38 inches. This is a much shallower depth, as expected with a denser material.

This illustrates how the same weight of infill can occupy different depths depending on its density. The turf pellet density is a critical factor when translating weight requirements into practical installation depths.

Advanced Considerations in Turf Infill Calculation

Beyond the basic area and depth, professional turf installation calculations might incorporate more nuanced factors:

- Turf Pile Height: Taller turf requires more infill to support the blades effectively.

- Tuft Gauge: The distance between rows of stitches. A tighter tuft gauge generally needs less infill for blade support.

- Stitch Rate: The number of stitches per linear inch. A higher stitch rate means more blades and potentially more infill density.

- Blade Count: The total number of synthetic grass blades per square inch. More blades can mean a denser infill layer is needed.

- Desired “Feel”: Sports scientists and coaches may specify infill depths and types to achieve a particular playing surface characteristic, such as a “softer” or “faster” feel.

These advanced considerations ensure that the infill coverage football fields receive is optimized for the specific sport, athlete safety, and desired performance outcomes.

The Lifespan of Artificial Turf and Infill

The infill, like the turf itself, has a lifespan. Over time, infill can:

- Degrade: Especially organic infill or crumb rubber exposed to UV radiation.

- Compact: Leading to reduced shock absorption and drainage.

- Migrate: Through wind, water, and player movement.

- Become Contaminated: With debris, organic matter, or foreign objects.

Therefore, periodic replenishment or even complete removal and replacement of infill is part of long-term turf maintenance pellets strategy. The frequency of these interventions depends heavily on usage and the quality of the initial installation.

Environmental and Cost Implications

The choice of infill material also carries environmental and cost implications.

- Crumb Rubber: Utilizes recycled tires, diverting them from landfills. However, there have been concerns about the release of volatile organic compounds (VOCs) and heavy metals from recycled rubber, though many studies suggest these risks are minimal with modern, properly processed materials.

- Sand: A natural resource, but quarrying can have environmental impacts. It’s also heavy, increasing transportation costs and carbon footprint.

- TPE/Synthetic Infills: Manufactured materials with a higher upfront cost, but often offer superior performance and longevity. Their production can have its own environmental footprint.

- Natural/Organic Infills: Biodegradable and renewable, offering a strong eco-friendly profile. Their durability and long-term performance can vary.

The total artificial turf infill amount directly impacts the initial cost of a field and its ongoing maintenance expenses. A larger quantity of a more expensive infill material will naturally lead to a higher overall investment.

Frequently Asked Questions (FAQ)

Q1: How often does a football field need new infill?

A: This varies greatly. A well-maintained field might only need top-ups every 1-3 years. However, fields with very heavy use may require more frequent maintenance. Complete replacement of infill might be considered every 8-12 years as part of the overall turf system replacement.

Q2: Can I use any type of sand as infill?

A: No. It’s crucial to use specific types of sand, such as silica sand, that are rounded and appropriately graded. Sharp or angular sands can damage the turf fibers and are not ideal for shock absorption.

Q3: Does infill make the turf softer?

A: Yes, the infill is essential for the shock absorption that contributes to a softer playing surface. The amount and type of infill, along with the turf’s construction, all influence the overall softness and playability.

Q4: What is the role of infill in drainage?

A: The granular nature of the infill creates porous pathways, allowing water to drain through the turf system and into the underlying base layers. Without adequate infill, the turf can become waterlogged.

Q5: How do I know how much infill my specific field needs?

A: Consult the artificial turf manufacturer or a qualified installer. They can provide precise recommendations based on the specific turf system chosen, the intended use of the field, and local environmental conditions. They will consider football field dimensions and desired turf pellet density.