Ever tried to fix something metal and watched the glue just peel right off? Metal can be tough to bond. Regular adhesives often fail when faced with slick surfaces or harsh conditions. This leaves you with weak repairs that just don’t last. Choosing the perfect epoxy for metal feels like a confusing puzzle. You worry about rust, strength, and if the bond will hold up to heat or water.

Stop wasting time and money on the wrong products! This guide cuts through the confusion. We will show you exactly what makes an epoxy strong for metal. You will learn the differences between various types and how to pick the best one for your specific project, whether it’s a quick household fix or a heavy-duty repair.

Ready to create a permanent, rock-solid bond on your metal projects? Keep reading to master the art of metal adhesion and say goodbye to flimsy fixes forever.

Top Epoxy For Metal Recommendations

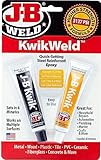

- J-B Weld Kwikweld: A Fast Setting Version Of The Original Cold Weld Two-Part Epoxy System That Provides Strong, Lasting Repairs To Multiple Surfaces. Perfect For Diy Household, Automotive, Marine, Craft Repair And Much More

- Cure And Set Time: After Mixing The Tubes At A 1: 1 Ratio, It Takes 6 Minutes To Set And 4-6 Hours To Cure. Once Cured, Kwikweld Can Be Tapped, Filled, Sanded, Molded And Drilled. Kwikweld’S Set And Cure Color Is Dark Grey

- Versatile And Dependable: J-B Weld Kwikweld Is Steel Reinforced, Has A Tensile Strength Of 3127 Psi And Can Withstand Temperatures Up To 230 Degrees Fahrenheit (110 Degrees Celsius). When Fully Cured, Kwikweld Is Waterproof And Resistant To Petroleum, Chemical And Acid

- Surface Applications: Metal, Plastic & Pvc, Wood, Concrete, Ceramic & Tile, Fiberglass And More

- Dries clear: Our Gorilla Tough epoxy resin dries clear for a clean finish and incredibly durable hold; perfect for household and automotive repairs

- 5 minute epoxy: This epoxy resin kit in just one applicator has a 5 minute set time, plenty for repositioning and adjusting

- Gap filling: Gorilla resin epoxy also acts as a gap filler, filling voids and bonding uneven or vertical surfaces

- Water resistant: Our clear epoxy resin withstands moderate exposure to water for extra durability

- Easy-to-use syringe: Gorilla Epoxy has separate barrels of epoxy resin and hardener to keep the epoxy from hardening; the syringes dispense evenly and include a cap for multiple uses

- J-B WELD ORIGINAL PRO SIZE: Professional 5 OZ Tubes of the Original Cold Weld two-part epoxy system that was designed as an alternative to torch welding. J-B Weld Original provides strong, lasting repairs to multiple surfaces and creates a bond stronger than steel. Perfect for DIY household, automotive, marine, craft repair and much more.

- CURE AND SET TIME: After mixing the tubes at a 1:1 ratio, it takes 4-6 hours to set and 15-24 hours to cure. Once cured J-B Weld Original can be tapped, filled, sanded, molded and drilled. J-B Weld Original set and cure color is dark grey.

- VERSATILE AND DEPENDABLE: J-B Weld Original is steel reinforced, has a tensile strength of 5020 PSI and can withstand temperatures up to 550 degrees Fahrenheit (287 degrees Celsius. When fully cured, J-B Weld Original is waterproof and resistant to petroleum, chemical and acid.

- SURFACE APPLICATIONS: Metal, Plastic & PVC, Wood, Concrete, Ceramic & Tile and Fiberglass.

- DO IT YOURSELF: Big or small, you can DIY it with J-B Weld. Our heavy duty epoxy and adhesives repair & restore it right the first time. J-B Weld delivers superior performance, quality, and results for the World’s Strongest Bond.

- J-B Weld Steelstik: A Hand Mixable Two Part Epoxy Putty Stick That Is Steel Reinforced & Non-Rusting To Quickly Repair Or Rebuild Anything Made Of Metal! J-B Weld Steelstik Is Certified By The Nsf And Is Safe For Contact With Potable Water

- Cure And Set Time: After Kneading The Two Part Formula Together By Hand, Steelstik Takes 5 Minutes To Set And Cures In 1 Hour. J-B Weld Steelstik Set And Cure Color Is Dark Grey

- Product Features And Strength: J-B Weld Steelstik Has Lap Shear Strength Of 900 Psi, Can Withstand Continuous Temperatures Up To 350F (176C ) And Intermittent Temperatures Of 450F (232C), And Is Chemical Resistant Against Petroleum, Hydraulic Fluids And Other Chemicals When Fully Cured. Steelstik Can Be Molded, Shaped, Sanded, Drilled And Tapped

- Surface Applications: Iron & Stainless Steel, Copper & Brass, Aluminum & Bronze, Fiberglass And Plastic & Pvc

- J-B Weld is The Original Cold-Weld two-part epoxy system that provides strong, lasting repairs to metal and multiple surfaces. Mixed at a ratio of 1:1, it forms a permanent bond and can be shaped, tapped, filed, sanded and drilled after curing. At room temperature, J-B Weld sets in 4-6 hours to a dark grey color. Full cure is reached in 15 hours. J-B Weld has a tensile strength of 5020 PSI and sets to a hard bond overnight. It can withstand temperatures up to 550°F when fully cured

- CURE AND SET TIME: J-B Weld Original High-Strength Syringe sets in 4-6 hours and cures in 15 hours.

- STRENGTH: J-B Weld Original Syringe has tensile strength of 5020 PSI.

- GREAT FOR: Great for household repairs, automotive, plumbing, marine, crafts and more.

- DO IT YOURSELF: Big or small, you can DIY it with J-B Weld. Our heavy duty epoxy and adhesives repair & restore it right the first time. J-B Weld delivers superior performance, quality, and results for the World’s Strongest Bond.

- J-B WELD ORIGINAL: The Original Cold Weld two-part epoxy system that was designed as an alternative to torch welding. J-B Weld Original provides strong, lasting repairs to multiple surfaces and creates a bond stronger than steel. Perfect for DIY household, automotive, marine, craft repair and much more.

- CURE AND SET TIME: After mixing the tubes at a 1:1 ratio, it takes 4-6 hours to set and 15-24 hours to cure. Once cured, J-B Weld Original can be tapped, filled, sanded, molded and drilled. J-B Weld Original’s set and cure color is dark grey.

- VERSATILE & DEPENDABLE: J-B Weld Original is steel reinforced, has a tensile strength of 5020 PSI and can withstand temperatures up to 550 degrees Fahrenheit (287 degrees Celsius). When fully cured, J-B Weld Original is waterproof and resistant to petroleum, chemical and acid.

- SURFACE APPLICATIONS: Metal, Plastic & PVC, Wood, Concrete, Ceramic & Tile and Fiberglass.

- DO IT YOURSELF: Big or small, you can DIY it with J-B Weld. Our heavy duty epoxy and adhesives repair & restore it right the first time. J-B Weld delivers superior performance, quality, and results for the World’s Strongest Bond.

- Need a fix that holds fast and lasts? Our professional-grade epoxy sets in just 5 minutes and cures to a steel-like strength within 24 hours. It creates a permanent, waterproof bond that can be drilled, sanded, and painted, making repairs stronger than the original material.

- Stop buying separate adhesives for every project! This versatile glue bonds metal, stainless steel, aluminum, plastic, ceramic, wood, glass, and concrete. Whether you're fixing a leaky pipe (plumbing), a cracked bumper (automotive), a broken vase, or a loose tile, one kit handles it all.

- Worried about heat, cold, or chemicals ruining your repair? Our formula is built tough. Once cured, it withstands temperatures from -54°C to 287°C (-65°F to 548°F) and resists oil, fuel, and many chemicals. Ideal for engine bay repairs, radiator fixes, and outdoor applications.

- No messy mixing or guesswork. The pre-filled 1:1 ratio syringe ensures perfect mixing every time. Simply dispense, blend, and apply. The paste-like, mayonnaise consistency won't drip on vertical surfaces. Includes a reusable cap to save leftover glue for future jobs.

- A cost-effective essential for every home, garage, and workshop. Repair radiators, fuel tanks, tools, toys, furniture, gutters, and marine equipment. Trusted by DIY enthusiasts and professionals for emergency repairs, routine maintenance, and creative projects. Your durable solution is just 5 minutes away.

- J-B Weld Steelstik: A Hand Mixable Two Part Epoxy Putty Stick That Is Steel Reinforced & Non-Rusting To Quickly Repair Or Rebuild Anything Made Of Metal! J-B Weld Steelstik Is Certified By The NSF And Safe For Contact With Potable Water.

- Cure And Set Time: After Kneading The Two Part Formula Together By Hand, Steelstik Takes 5 Minutes To Set And Cures In 1 Hour. J-B Weld Steelstik Set And Cure Color Is Dark Grey.

- Product Features And Strength: J-B Weld Steelstik Has a Tensile Strength of 4000 PSI, Can Withstand Continuous Temperatures Up To 350F (176C ) And Intermittent Temperatures Of 450F (232C), And Is Chemical Resistant Against Petroleum, Hydraulic Fluids And Other Chemicals When Fully Cured. Steelstik Can Be Molded, Shaped, Sanded, Drilled And Tapped

- Surface Applications: Iron & Stainless Steel, Copper & Brass, Aluminum & Bronze, Fiberglass And Plastic & Pvc

- DO IT YOURSELF: Big or small, you can DIY it with J-B Weld. Our heavy duty epoxy and adhesives repair & restore it right the first time. J-B Weld delivers superior performance, quality, and results for the World’s Strongest Bond.

Choosing the Right Epoxy for Metal: Your Buying Guide

Epoxy is a super strong glue. It sticks things together really well. When you need to fix metal or join metal pieces, the right epoxy makes all the difference. This guide helps you pick the best one.

Key Features to Look For

When you shop for metal epoxy, look closely at these important parts:

1. Bond Strength

- High Tensile Strength: This means how much pulling force the cured epoxy can handle before breaking. Stronger is usually better for heavy-duty jobs.

- Shear Strength: This measures how well the epoxy resists forces that try to slide the glued surfaces past each other.

2. Curing Time

- Fast-Setting: Some epoxies harden in minutes. This is great for quick fixes.

- Slow-Setting: Others take hours. These often create a stronger, more flexible bond because they have more time to settle.

3. Environmental Resistance

- Waterproof/Water Resistance: If your metal item goes outside or near water, choose a waterproof epoxy.

- Chemical Resistance: Oil, gasoline, or cleaning chemicals can weaken weak glues. Look for resistance labels.

4. Application Type

- Gap Filling: If the metal pieces don’t fit perfectly together, you need a thick epoxy that fills the empty space.

- Clear vs. Opaque: Clear epoxies look better if the bond shows. Opaque ones often offer more strength.

Important Materials in Metal Epoxy

Most strong metal epoxies have two parts. You mix them together to start the hardening process.

The Resin (Part A)

This is usually the main liquid part. It contains the chemicals that start the reaction.

The Hardener (Part B)

This chemical mixes with the resin. When they combine, they create a very hard plastic bond.

Additives for Metal

Good metal epoxies often have special fillers mixed in. These can be tiny metal powders or strong fibers. These additives help the epoxy grab onto the smooth metal surface better and make the final bond tougher.

Factors That Improve or Reduce Quality

Surface preparation is the biggest factor in quality. A great epoxy will fail on a dirty surface.

Improving Quality

- Surface Cleaning: Always clean the metal first. Remove all rust, dirt, grease, and old paint. Use sandpaper or a wire brush to rough up the surface slightly. This gives the epoxy something to stick to.

- Proper Mixing Ratio: Follow the package directions exactly when mixing Part A and Part B. Too much hardener or too little resin ruins the cure.

Reducing Quality

- Moisture: Water left on the metal prevents the epoxy from bonding correctly.

- Cold Temperatures: Applying epoxy when it is too cold slows down the curing process, sometimes stopping it completely.

User Experience and Use Cases

How you use the epoxy changes what you need to buy.

DIY Home Repairs

For fixing a broken metal railing or a loose hinge, a general-purpose, medium-strength epoxy works well. Look for one that is easy to mix.

Automotive and Machinery

When you repair engine parts or tools, you need high-heat resistant epoxy. These products handle vibration and tough conditions better.

Crafting and Jewelry

Hobbyists often need a clear, low-viscosity (thin) epoxy. This flows easily and dries crystal clear for decorative work.

10 Frequently Asked Questions (FAQ) About Metal Epoxy

Q: Can I use epoxy on rusty metal?

A: No. You must remove all loose rust before applying epoxy. Rust stops the glue from sticking to the good metal underneath.

Q: How long does metal epoxy usually last?

A: A properly applied epoxy bond can last for many years, often as long as the metal itself, especially if it resists water and chemicals.

Q: Do I need to prime the metal before using epoxy?

A: Most strong metal epoxies do not require a separate primer. Roughening the metal surface is usually enough.

Q: Can metal epoxy withstand high heat?

A: Some specialized epoxies can. Check the product label for a maximum temperature rating if you are fixing engine components.

Q: What is the difference between epoxy and super glue?

A: Super glue (cyanoacrylate) dries very fast and is brittle. Epoxy is a two-part system that cures slower but creates a much thicker, stronger, and more gap-filling bond.

Q: Can I sand or paint cured epoxy?

A: Yes. Once fully hardened, most epoxies can be sanded smooth and painted to match the surrounding metal.

Q: What if I accidentally mix too much hardener?

A: If you add too much hardener, the epoxy may cure too quickly, become extremely brittle, and might not reach its full intended strength.

Q: Is metal epoxy safe to use indoors?

A: Yes, but you should always work in a well-ventilated area. The fumes during the mixing and curing stages can be strong.

Q: What is the best way to clean up uncured (wet) epoxy?

A: Acetone or rubbing alcohol usually works best for cleaning up wet epoxy from tools and skin before it hardens.

Q: Does epoxy bond well to aluminum?

A: Aluminum can be tricky because it forms a natural oxide layer. You must aggressively clean and scratch the aluminum surface for the epoxy to create a durable bond.